Quality

Control &

Certifications

QUALITY

CONTROL &

CERTIFICATIONS

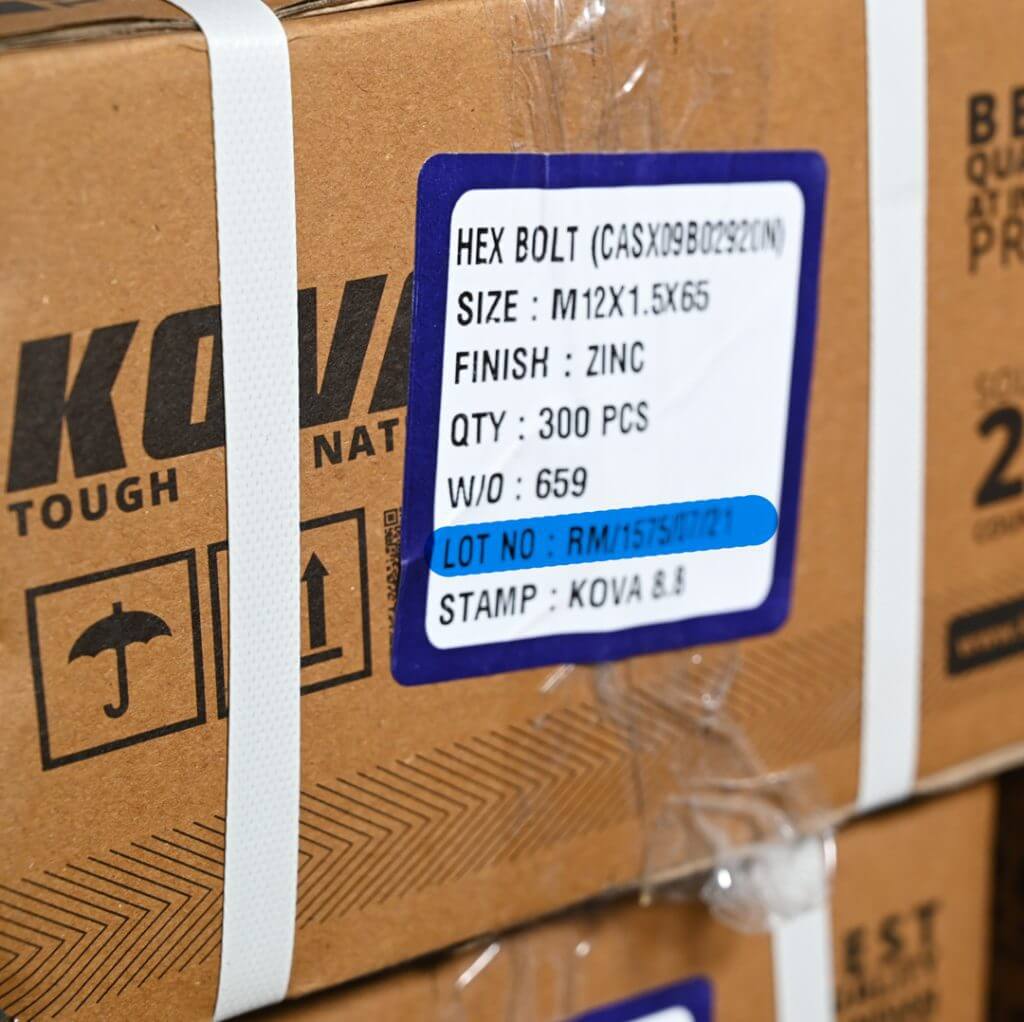

At KOVA, we focus on full batch traceability of every product that is manufactured at our unit, starting from the chemical composition a unique batch number is created for every product which is carried through out at every stage of production. This unique batch number is also labelled on the packaging of the product.

KOVA, is certified for “IATF 16949 : 2016” for the production of high quality automotive fasteners and “CE” for the production of structural bolting assemblies as per EN 15048 & EN 14399. Our state of the art production unit ensures durable product with excellent finishing.

Multiple tests and checks are done at every stage of production process to ensure the chemical, mechanical and dimensional accuracy of each and every fastener.

| NON DESTRUCTIVE TEST EQUIPMENTS | RANGE | QUANTITY |

|---|---|---|

Hardness Tester Rockwell | HRB / HRC | 2 No. |

| Hardness Tester Vicker Scale | - | 01 No. |

| Profile Projector | - | 01 No. |

| Metallurgical Microscope | - | 01 No. |

| B. F. Testing Machine For Carrogated Box | - | 01 No. |

| DESTRUCTIVE TEST/MECHANICAL TEST EQUIPMENTS | CAPACITY | QUANTITY |

|---|---|---|

UTM (Universal Testing Machine) | 40 TON / 100 TON | 2 No. |

| Impact Testing Machine | - | 01 No. |

| Spectometer | - | 01 No. |

| ELECTROPLATING INSTRUMENTS | QUANTITY |

|---|---|

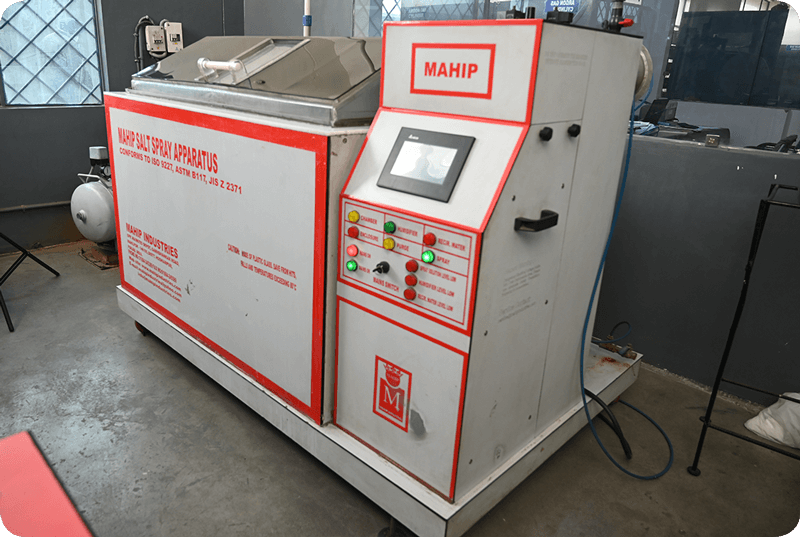

| Salt Spray Chamber | 01 No. |

| Coating Thickness Guage | 02 No. |

At Kova Fasteners Pvt Ltd., we focus on full batch traceability of every product that is manufactured at our unit, starting from chemical composition a uniquie batch number is created for every product which is carried throught out at every stage of production. This unique batch number is also labeled on the packaging of the product.